Sheet but welding machines

New generation of welding devices WIDOS type PSM was developed to meet highest requirements in plastic sheets welding. Two basic types of devices are available - with manual control (working lenght up to 2000 mm, wall thickness up to 20 mm) and with pneumatic (air-operated) or actuator (working lenght up to 4000 mm, wall thickness up to 60 mm). By manual controlled machines is basic construction adapted from WIDOS 2500 welding machine - welding tables shift is realized by turning wheel, and pressure welding force is created by pressure spring with adjustable scale. Reliable clamping of welding sheets is ensured by threaded spindles, which allows sufficient clamping forces also by smallest versions of welding devices. Welding surfaces heating is realized via heating lath equiped with non-stick layer. Air-operated machines WEGENER are used for bigger working lenghts, and actuator is used only for devices with CNC control unit. By these devices is generated clamping force up to 100 kN, which ensures secure clamp also by biggest plastic sheets dimensions.

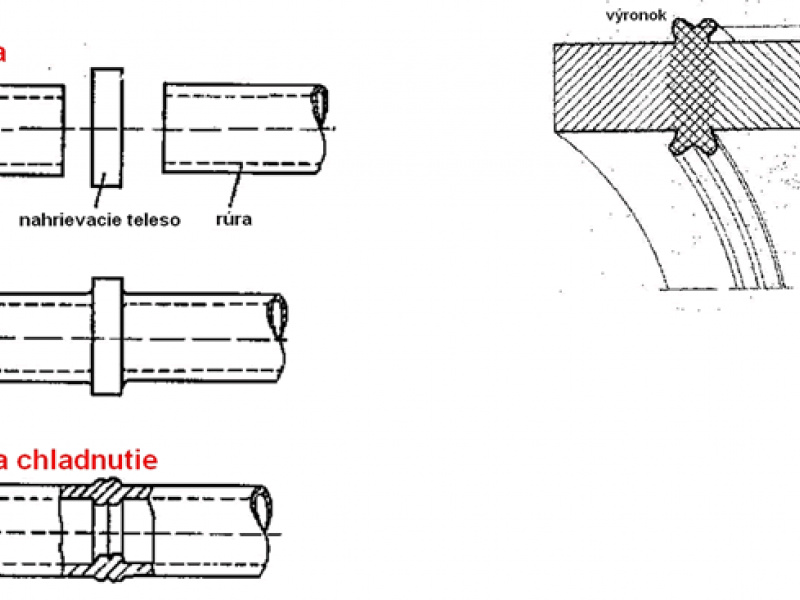

Butt welding principle

Butt welding (or pressure welding) is contact welding, it means, that welded surfaces are warmed by heating element. By pipe welding is used so-called "mirror", by plastic sheets welding is used so-called "heating lath". Welded surfaces must be smoothly machined before welding - in case of plastic pipes the planer is used. Then an overlap is checked - by pipe welding can not be bigger than the 0,1 x wall thickness and welded surfaces must be cleaned up from grease and mechanical dirts. Next, under the exact set pressure (so-called "adjustable pressure") pipe endings are pushed on heating element, warmed at welding temperature. After the first phase pipe endings heating elapse (so-called "adjustment"), a beade appears on welded surface circumference. Now, the pressure must be minimalized and second phase of heating (so-called "in-depth heating") begin. After second phase is being elapsed the heating element must be removed from inbetween two welded pipes, and within the shortest possible time the heated pipe endings are put close to each other. This phase is called rearrangement. Subsequently, the pressure increasing phase is begin, where the pressure on welding pipe endings is gradually increasing up to the level of welding pressure. Under this pressure welded parts remains until the welding joint is fully cool down, in other words - during entire cooling phase.

For entire welding process, these three physical quantities are crucial: time, temperature and pressure. These quantities are exactly determined by technical standards depending on welding material type, wall thickness and pipe diameter.