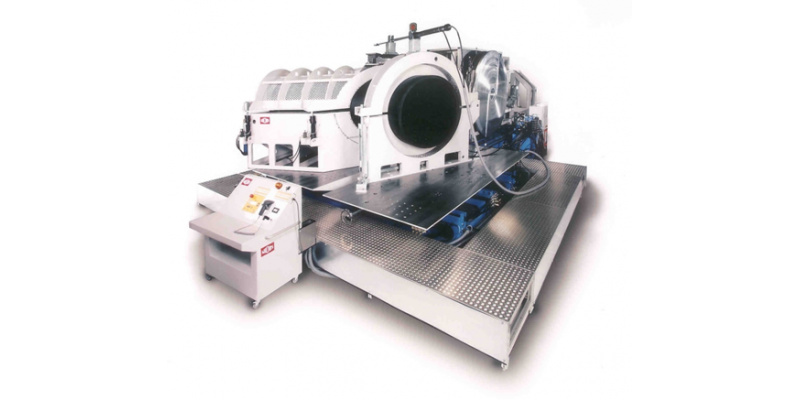

WIDOS 16000 WM / 16000 WS CNC

Workshop devices for butt welding of pipes and fittings from PE, PP and PVDF for diameters from DA 800 to DA 1600 mm, with hydraulic shift or drive unit clamping tool. Welding unit is mounted on the massive base frame, with two movable welding tables on it . Alternatively can be supplied with SPA protocol unit, or CNC control unit. Clamping tools can swivel about 15°, or 22,5° for segmented bends or T-pieces welding.

| Machine type | WIDOS 16000 WM* | WIDOS 16000 WM CNC* |

| Range in mm | 800 - 1600 | 800 - 1600 |

| Basic machine | ||

| Servo-drive unit | ||

| Electrical planer | ||

| Heating element | ||

| CNC or SPA unit | ||

| Base frame | ||

| Hydraulic clamping unit | optional | optional |

| Reducer inserts | ||

| Reducer inserts DA 800 | ||

| Reducer inserts DA 900 | ||

| Reducer inserts DA 1000 | ||

| Reducer inserts DA 1100 | ||

| Reducer inserts DA 1200 | ||

| Reducer inserts DA 1400 | ||

| Reducer inserts DA 1600 | basic clamping tools | basic clamping tools |

| Accessories | ||

| Flange adapter | ||

| Left adjustable table | ||

| Second working hydraulic valve | optional | optional |

| Barcode reader | ||

| USB connector | ||

| SD memory card | ||

| Welding pass | ||

| Pipe data card | ||

| Operating software | ||

* an extension component for fabrication of welded 45°, 60° a 90° T-pieces (for dimension up to DA 1600) is available

Manual plastic welding machine for the heating element butt welding of PE and PP pipes and fittings from OD 800 (32“ IPS) up to OD 1600 (63“ IPS). The machine has been especially designed for the efficient fabrication of fittings, bows and T- resp. Cross-pieces of the highest quality in the workshop. The welding machine is based on an extremely solid and torsion-free basic frame with precise high-capacity guidings and with a symmetrically arranged cylinder battery. The machine bed is performed in a flat construction in order to keep the table level as low as possible for easy equipment with clamping tools and welding pieces. The applied table drive enables exactly controllable and huge forces, features extraordinarily low driving forces and thus warrants a constant movement during the welding cycle. Two machine tables are built on the basic frame which are both stored on precise and high-capacity guiding units and which can be diagonally shifted via spindles for misalignment compensation. The tables are stored afloat in order that balanced conditions during planing, aligning and heating are warranted. The tables are automatically limited in the opening stroke in order to shorten the tear-off ways during change-over.

The planer is electrically powered by an extremely high-torsional three-phase drive motor and disposes of an electronic start smoother for shock-free working. The special planer discs are optimized for the highest cutting performance and quiet drive by several cutting zones with adjustable chip flute width, and due to the large overhang besides the extreme center storing they are secured with additional support bearings against bending loads and bulges. The planer drives between the machine tables in electrical manner and is, in addition, hydraulically supported and locked within the treatment position. The anti-stick coated 4-zone heating element is precisely controlled in electronical manner and fulfills the highest demands with regard to lifetime and temperature distribution. By using individually replaceable heating devices you will obtain precise temperature distributions and this enables easy repairs and individual changes without replacing the entire unit. The heating element is suspended from a solid girder frame with compensation of thermal expansion and, for the quickest movements, it electrically drives in and out within the machine tables during the change-over time. In order to produce different fittings, there are clamping tools in different versions and operations. They are mounted onto the machine tables in predefined drilling templates and may be quickly installed, aligned and fixed in solid manner by a special system with threaded jackets. The handling of the clamping tools is controlled via remote control that may be directly taken to the needed spot by the operator in order that no dangerous situations occur due to inadequate sight.

For easier operation of the welding machine during equipping and clamping, the machine is surrounded by a revolving platform with anti-skid steps. It acts as revolving stairway for comfortable ascending and descending and also as additional operator protection in form of a front barrier against unintentional entering into crushing zones. Furthermore, a safety fence is assembled in the rear machine area which shields the movements of heating element and planer. As additional safety measure during automatic processes, cleaning of the planing chips and operation by several persons, you may temporarily deactivate the hydraulic movement of the welding tables by a peelable key holder.