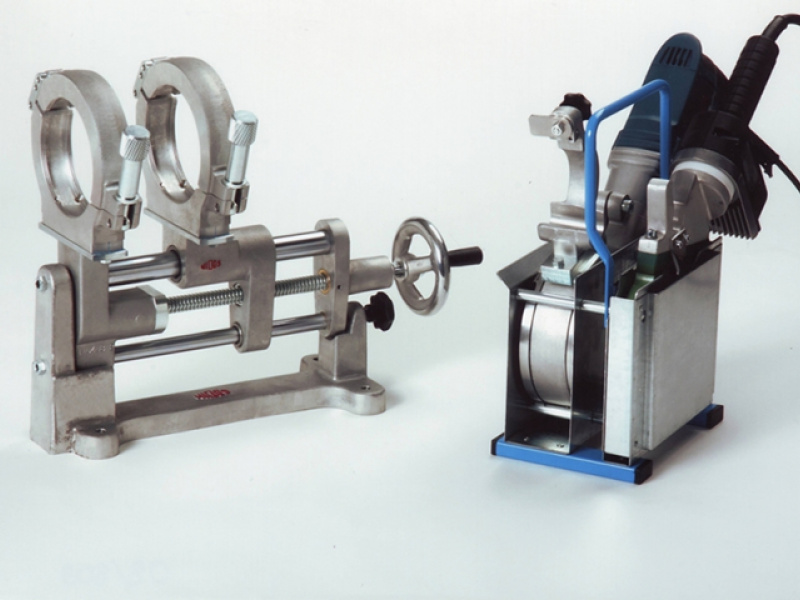

WIDOS Miniplast/Maxiplast

Light butt welding equipment for pipe and fittings welding from PE, PP and PVDF for diameters from DA 20 to DA 160 mm with mechanical shift jaws. Clamping tools can swivell about 15°, so you can weld also segmented bends or elbows. With Miniplast 2 T version you can fabricate welded T-shape pieces. An electric planer is available as a optional solution.

| Machine type | WIDOS MINIPLAST 2 |

WIDOS MINIPLAST 2 T |

WIDOS MINIPLAST 2 IR |

WIDOS MAXIPLAST |

| Range in mm | 20 - 110 | 20 - 110 | 20 - 110 | 50 - 160 |

| Basic machine | ||||

| Hydraulic power unit | ||||

| Electrical planer | optional | optional | ||

| Mechanical planer | ||||

| Heating element | ||||

| Protection box | ||||

| CNC or SPA unit | ||||

| Infra-red heating control | ||||

| Table holder | ||||

| Transport case | ||||

| Reducer inserts | ||||

| Reducer inserts DA 20 | ||||

| Reducer inserts DA 25 | ||||

| Reducer inserts DA 32 | ||||

| Reducer inserts DA 40 | ||||

| Reducer inserts DA 50 | ||||

| Reducer inserts DA 63 | ||||

| Reducer inserts DA 75 | ||||

| Reducer inserts DA 90 | ||||

| Reducer inserts DA 110 | basic clamping tool | basic clamping tool | basic clamping tool | |

| Reducer inserts DA 125 | ||||

| Reducer inserts DA 140 | ||||

| Reducer inserts DA 160 | basic clamping tool | |||

| Accessories | ||||

| Flange adapter | ||||

| Barcode reader | ||||

| USB connector | ||||

| SD memory card | ||||

| Welding pass | ||||

| Pipe data card | ||||

| Operating software | ||||

Mobile plastic welding machines for the heating element butt welding of pipes and fittings made out of polyolefines. The solid basic machine has two aluminium clamping tools swivelling eacht to 15° for the fabrication of segmented bends. By using different reducer inserts, all clampming options can be realized. For fittings with extremely short legs, solid steel clamping tools in small version are available.

The solid base with ball-bearing guidings, spindle and power input damped by springs enables quick movements for short change-over times as well as a soft pressure build-up. Due to the compact and solid design, the machine is ideally suitable for the usage at places with difficult access under on site conditions. For the stationary usage, an additional basement is available which enables to use the machine as table set.

The solid planer with manual/electric drive has been optimized with respect to a most simple handling. The electronically controlled heating element has an anti-stick coating of high quality, an exterman mains switch and control lamps for an interval checking. The exact temperature control meets all requirements of DVS 2208.

For the safe sotrage of heating element and planer, a solid and easily portable heat-protected box is available. The complete machine can be transported and stored in a transport case with additional compartments for all reduction inserts.