Electrofusion welding machines

Electrofusion welding machines are designed for plastic pipes welding from PE and PP using socket without diameter limitation (depending on socket manufacturers capabilities). These are universal - can be used for all available types of sockets. They are supplied in semi-automatic (manual imput of welding datas) and automatic design (welding datas input via barcode) with welding protocol option available, or without it.

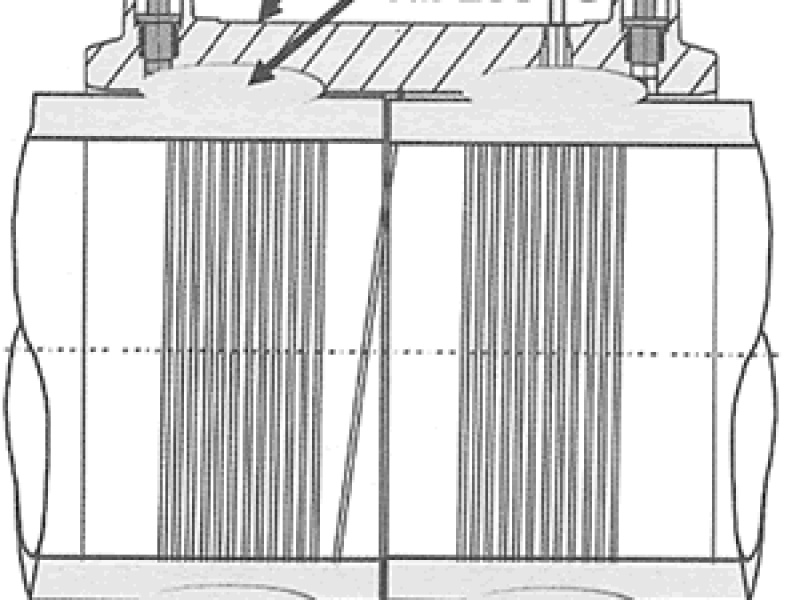

Electrofusion welding principle

Basically, it is very similar type to socket welding, with one difference - warming is not realized by heating element, but with using the resistance winding, which is build-in in basic material of socket (so-called "electro socket").

Welded parts endings must be clean off grease and oxidation layer (using the scraper). Then the electro socket is slided on and is recommended fixate the welded parts in positioners. Subsequently the welding cable is attached to electro socket connectors. Welding parameters (voltage, current, time) is possible to input two ways - manually, according to tables using control buttons or via barcode reader directly from electro socket. These datas can be adjusted by welding machine depending on outer temperature. When the welding process is started, welding device is regulating electrical current supply into socket resistance winding, which causes welded parts melting in point of joint. After finishing the welding phase, the cool down period is elapsing. During this phase the welding joint can not be loaded and it is suitable to let it fixate into the positioners.

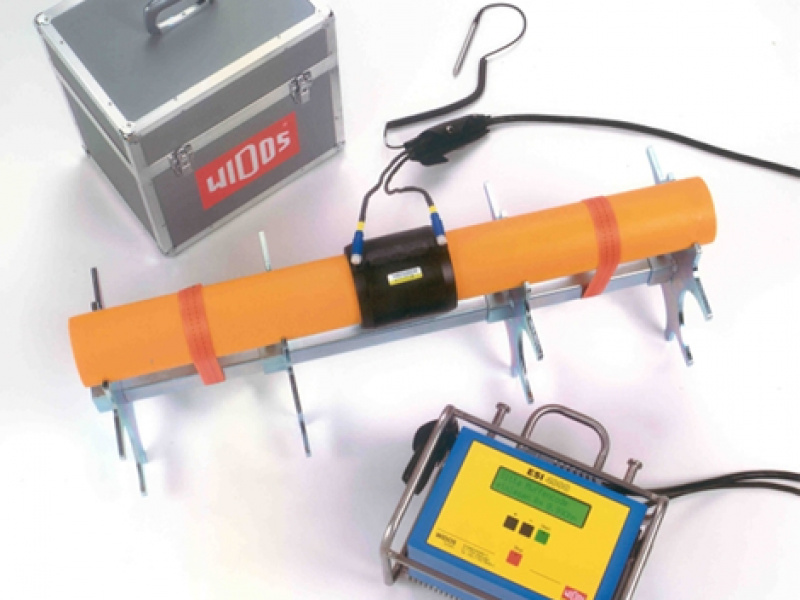

Workshop welding machines range of products:

- WIDOS ESI 2000 / ESI 4000

- HÜRNER HST 300 MANUAL / JUNIOR / PRINT / PRICON

- SAURON (CTF FRANCE) BARBARA / ONDINE / JULIE